Multi-Techno Integrated Solution

Multi-techno ERP for Textile Management System

- Optimize production and inventory with a Textile Management System.

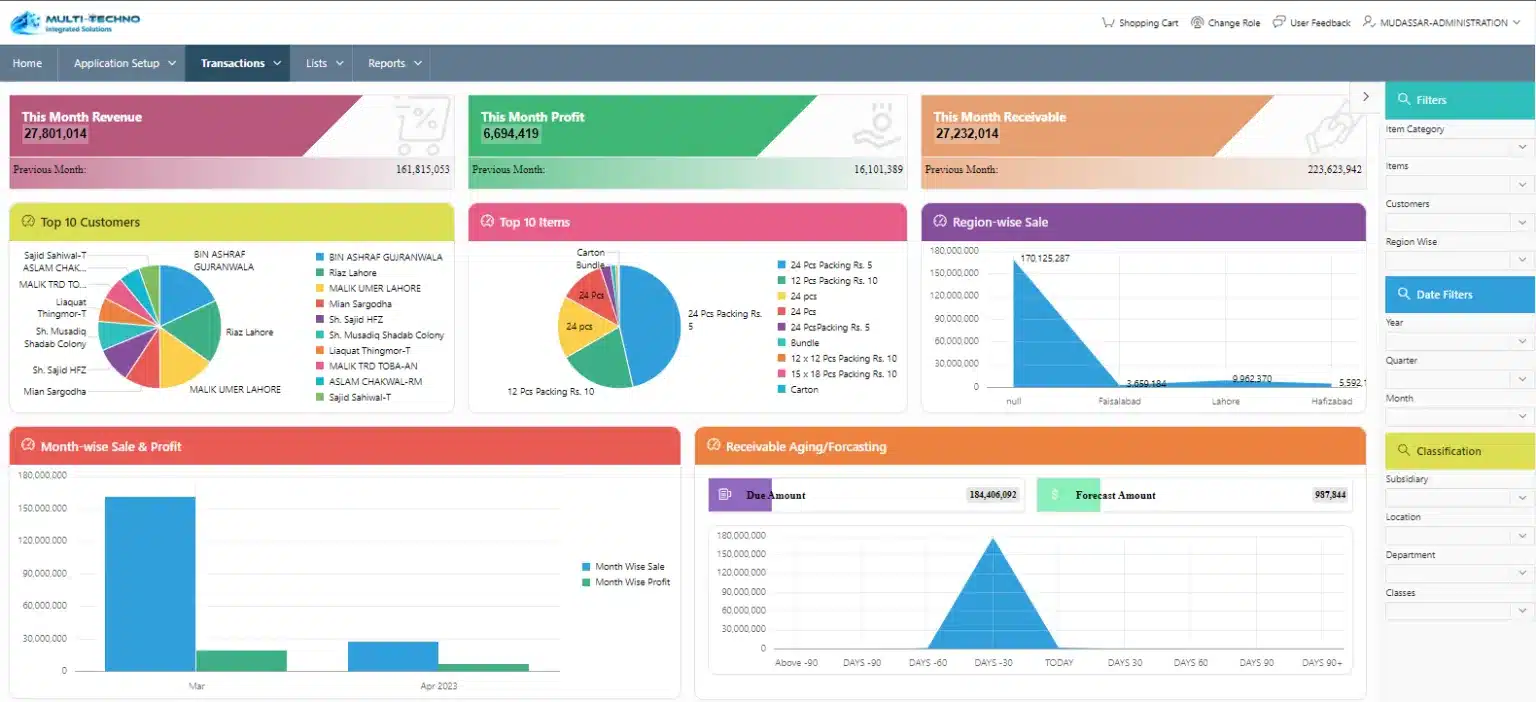

- Enhance profitability with real-time insights and automation.

- Streamline processes using advanced textile manufacturing software.

Request for Demo

Optimize Textile Manufacturing with Multi-Techno ERP Integration

Revolutionize your global textile manufacturing operations with Multi-Techno ERP Integration’s Textile Management System. Our web-based solution simplifies operations, enhances productivity, and ensures seamless order management. Track work orders efficiently through comprehensive reports and benefit from features like Operations and Routing, Bill of Material management, Dyeing Recipe systems, and streamlined production planning. The system’s Manufacturing ERP module provides insightful reports for tracking work order status, production analytics, and Bill of Material reports. From efficient work order generation to detailed invoice and packing list management, our Textile Management System empowers your business with a holistic solution for enhanced efficiency and profitability in the Textile Industry.

Revolutionize Your Textile Manufacturing Operations

Streamline your textile manufacturing operations globally with our simple, stylish, responsive web-based Textile Management System powered by Multi-Techno ERP.

Tracking Status and Streamlining Workflows

Stay on top of orders and enhance productivity with our streamlined order management system.

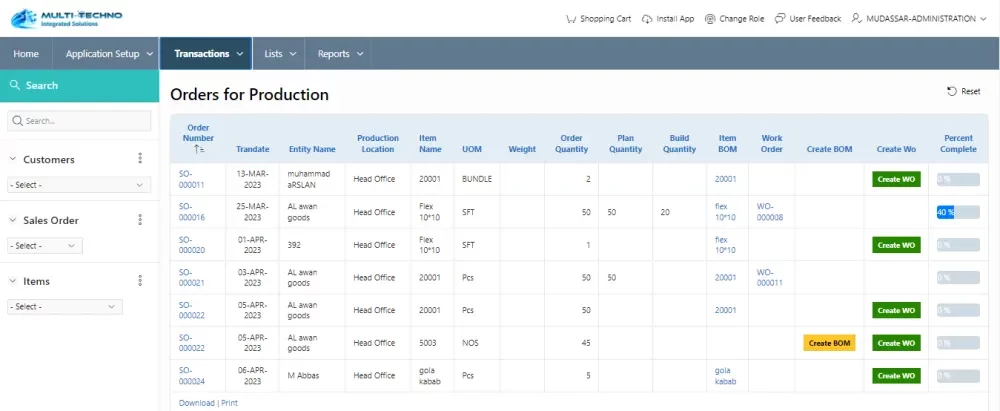

Work Order

Efficiently track and manage your work orders with our comprehensive work order report.

Features of Textile Management System

Operations and Routing (OAR)

A route defines the organization of the manufacturing process. In other words, it establishes the sequence of events. An operation like Assembly indicates a named stage in a path. Even so, the same process might occur numerous times in various ways with distinct operation numbers. Furthermore, ERP Implementation by Multi-techno helps in operating and routing.

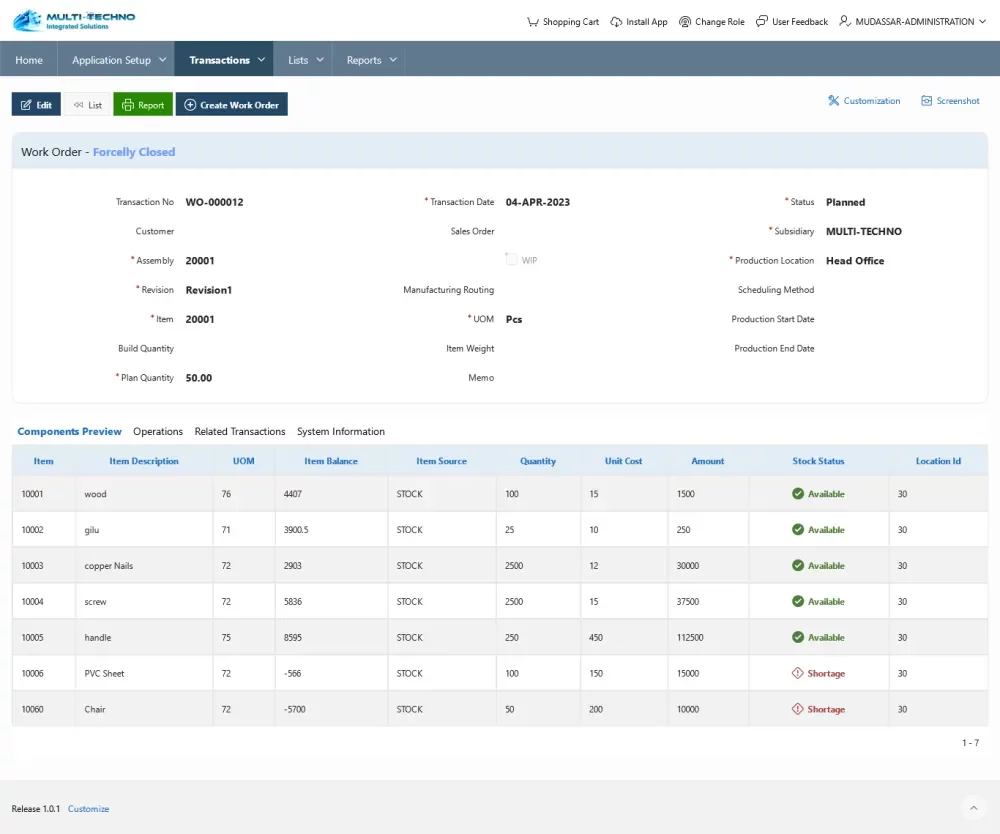

Bill of Material (BOM)

Bill of Material refers to raw materials used to produce textiles. Finally, the bill of material is the responsibility of a garment seller. They are following the confirmation of a garments export order. Moreover, the product sales company or factory marketer enters the product’s details into the Bill of Material software provided by the buying merchandiser.

Dyeing Recipe

Many textile industries have Dyeing Recipe Management System Software developed. The majority of textiles have a dying section. The centre of the dyeing process is the recipe. Dye recipes are organized in the Erp software of a dyeing recipe management system. As a result, automatic recipe management is critical for greater effectiveness in the dyeing system.

Work order

After the manufacturing order, the work order is generated. AA work order is a document with all the details about the order according to the operation. Your maintenance operation’s engine is work orders. They assist everyone from production engineers to workers in organizing, allocating, prioritizing, tracking, and completing Production activities.

Manufacturing reports

Manufacturing order

It is a type of order required to produce things and is divided into internal and contractual orders. Manufacturing guidelines are used to create the manufacturing order. Textile management system by multi-techno offers you that services.

Production planning

Production planning is an organizational procedure that takes place within a production company. Ensure enough raw materials, workers, and other essential goods are bought and available. To generate final products according to the timetable.

Manufacturing reports

Our Manufacturing ERP module includes several reports that may be used to track Work Order status, production analytics, and BOM reports. You may use a chart in these reports to provide a graphic image.

Invoice and packing list

The usage of packing slips to indicate the actual products received. Whereas an invoice is the order’s fiscal record, giving information. Such as the price of each product, payment conditions, transaction fee, the weight of the product, CBM, date, etc.

Our Satisfied Clients

About Us

ERP software and systems are designed and implemented by Multi-Techno, a registered company. By combining data from financials, sales, CRM, inventories, and operations, businesses can increase productivity, make better decisions, and increase profitability with the aid of our ERP System, a single, integrated software platform.

Quick Links

Contact Us

Office # 100, 101 Second Floor Kohinoor 1, Faisalabad, Pakistan