Multi-Techno Integrated Solution

Manufacturing ERP System

Transform Your Manufacturing Operations, Streamline Processes,

Boost Productivity and Optimize Resources

ERP for the Manufacturing Sector Optimizing Business Performance

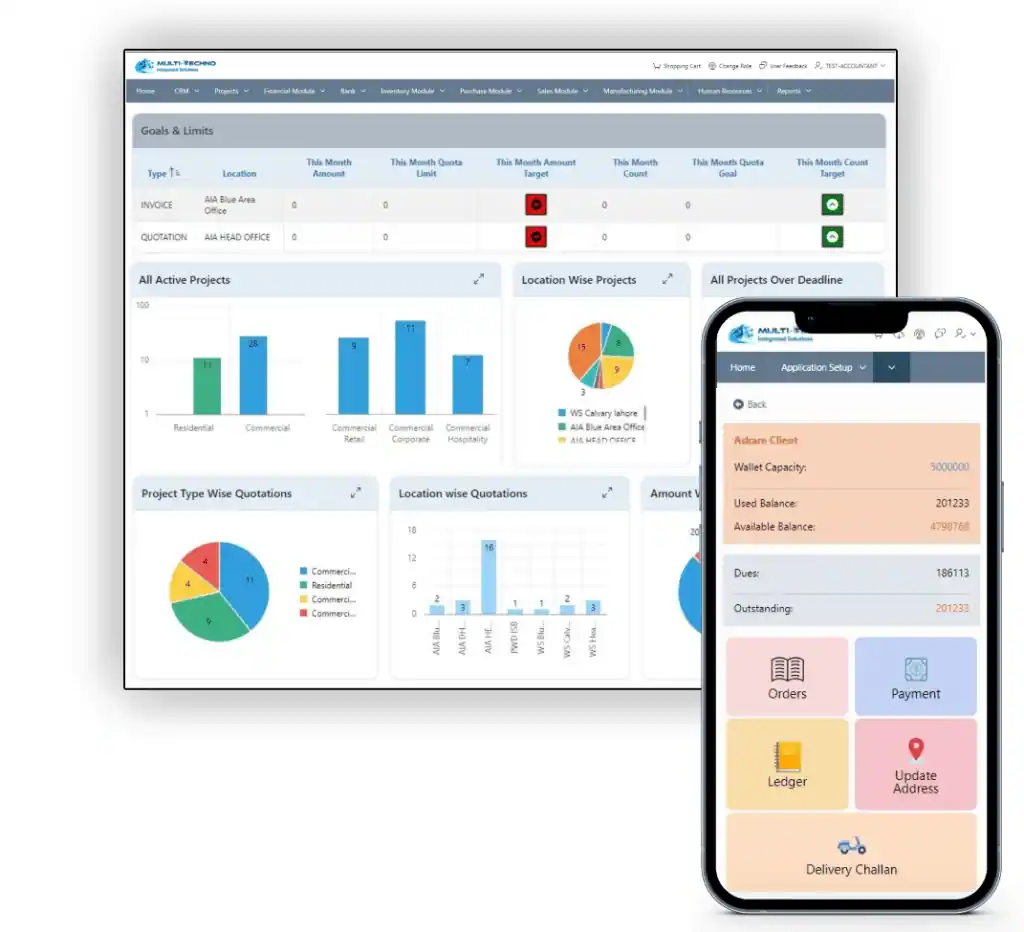

Enterprise Resource Planning (ERP) systems have revolutionized business operations, especially in the manufacturing sector. Our ERP solution is designed specifically for the manufacturing sector, offering robust tools to streamline processes, improve productivity, and ensure quality. Discover how our ERP system can transform your business and keep you ahead of the competition.

Modules of Manufacturing System

1. Production Management:

- Real-time monitoring of production processes.

- Automated scheduling and workflow management.

- Reduce downtime and improve efficiency.

2. Inventory Control:

- Accurate tracking of raw materials and finished products.

- Minimize waste and manage stock levels effectively.

- Just-in-time inventory management to reduce holding costs.

3. Quality Assurance:

- Integrated quality control processes.

- Ensure compliance with industry standards.

- Track and resolve issues quickly.

4. Supply Chain Management:

- Optimize procurement and supplier relationships.

- Real-time visibility into the supply chain.

- Improve delivery times and reduce costs.

5. Financial Management:

- Comprehensive financial reporting and analysis.

- Budgeting, forecasting, and cost control.

- Seamless integration with accounting systems.

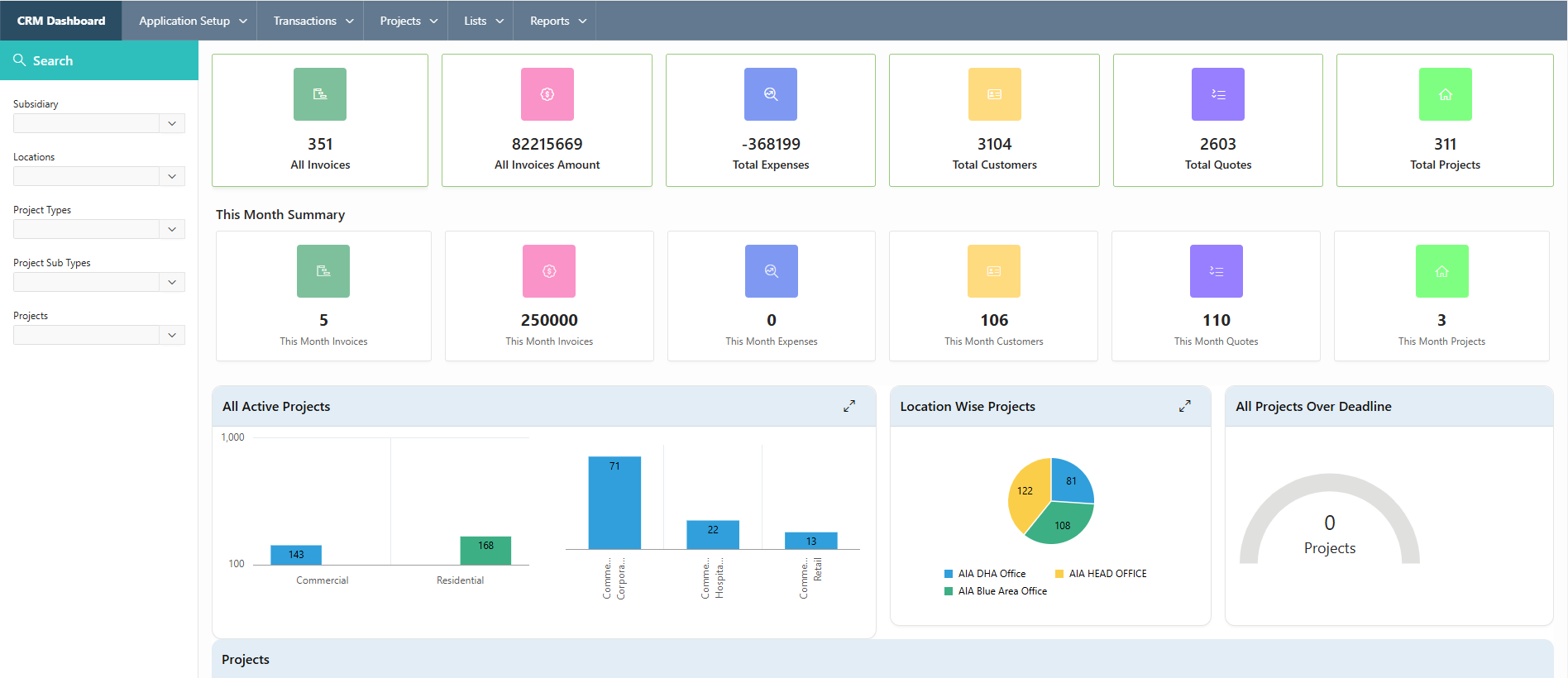

6. Customer Relationship Management (CRM):

- Manage customer interactions and sales processes.

- Improve customer satisfaction and retention.

- Track sales performance and identify new opportunities.

Why Choose Our ERP?

- Tailored for Manufacturing: Our ERP solution is designed specifically for the manufacturing sector, addressing unique challenges and requirements.

- Scalable and Flexible: Whether you’re a small manufacturer or a large enterprise, our ERP system scales with your business.

- User-Friendly Interface: Easy-to-use interface that requires minimal training.

- Strong security: Protect your data with advanced security features.

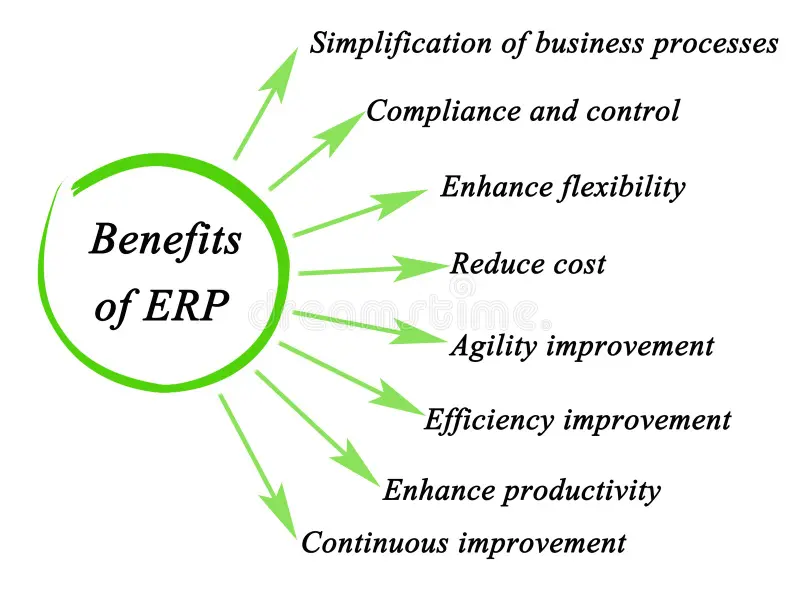

Benefits of ERP in the Manufacturing Sector

ERP systems in the manufacturing sector streamline processes, boost efficiency, and reduce operational costs. By integrating all business functions, ERP enhances decision-making and improves overall productivity.

Achieve Unmatched Operational Efficiency

One of the primary benefits of ERP systems in manufacturing is the significant improvement in operational efficiency. ERP systems streamline and automate business processes, reducing manual intervention and the likelihood of errors. This leads to faster production cycles, reduced lead times, and more efficient use of resources.

Enhanced Inventory Management

ERP systems offer real-time visibility into inventory levels, helping manufacturers maintain optimal stock levels and avoid stockouts and overstocks. Advanced inventory management features such as automated replenishment, demand forecasting, and lot tracking ensure that suitable materials are available at the right time, minimizing disruptions in production.

Better Resource Planning

Effective resource planning is critical for manufacturing success. ERP systems facilitate the efficient allocation and utilization of resources, including raw materials, machinery, and labor. By providing a centralized platform for planning and scheduling, ERP systems help manufacturers optimize production schedules, reduce downtime, and improve overall productivity.

Streamlined Supply Chain Management

ERP systems enhance supply chain management by providing end-to-end visibility and control over the entire supply chain. From procurement and supplier management to logistics and distribution, ERP systems enable manufacturers to manage their supply chains more effectively, reducing costs and improving delivery times.

Optimizing Business Performance with ERP

Manufacturing ERP streamlines business operations by integrating all fundamental processes into a centralized platform, improving efficiency and productivity.

Real-time Data and Analytics

One key advantage of ERP systems is their ability to provide real-time data and analytics. Manufacturers can access up-to-date information on production, inventory, sales, and financials, enabling them to make informed decisions quickly. Advanced analytics and reporting tools offer insights into key performance indicators (KPIs), helping manufacturers identify areas for improvement and track progress toward their goals.

Process Automation

ERP systems automate many routine and repetitive tasks, freeing up valuable time for employees to focus on more strategic activities. Automation reduces the risk of human error, improves consistency, and increases efficiency. ERP systems streamline operations across the entire manufacturing process, from order processing and invoicing to production scheduling and quality control.

Cost Reduction

ERP systems help manufacturers reduce costs by improving operational efficiency, inventory management, and supply chain processes. They also enable better financial management by providing accurate and timely financial data, assisting manufacturers in controlling expenses, managing budgets, and improving profitability.

Quality Control and Assurance

Maintaining high-quality standards is essential for manufacturers. ERP systems support quality control and assurance by providing tools for tracking and managing quality throughout the production process. Manufacturers can monitor product quality in real time, identify and address issues quickly, and ensure compliance with industry standards and regulations.

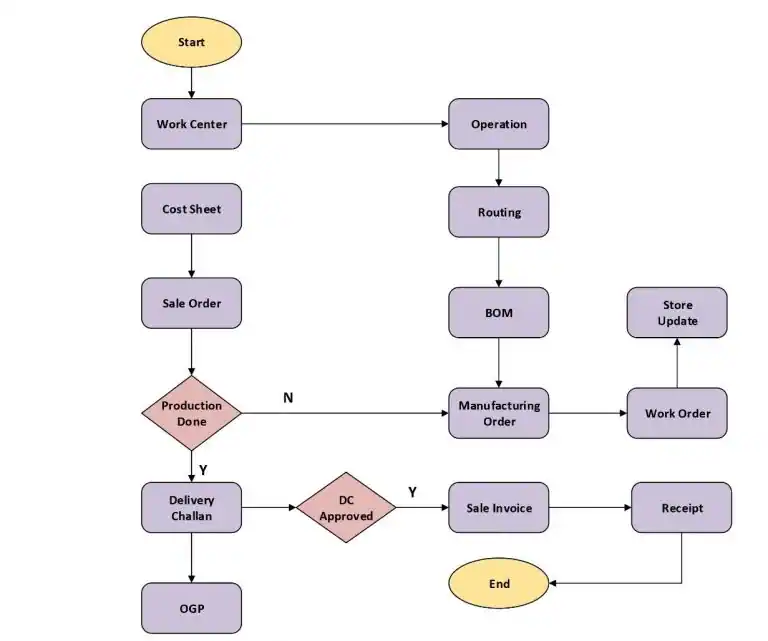

How ERP Works in the Manufacturing Industry

Integration of Business Processes

ERP systems combine different business operations into a unified, functional system. This integration eliminates data silos, ensures consistency, and enhances collaboration across departments. For example, information from the sales department can be seamlessly shared with production, procurement, and finance, enabling better coordination and decision-making.

Centralized Information System

A centralized information system is a core feature of ERP systems. All data is stored in a single database, providing the organization with a unified source of truth. This centralization improves data accuracy, reduces duplication, and ensures all departments access the same information.

Production Planning and Scheduling

ERP systems play a crucial role in production planning and scheduling. By considering factors such as demand forecasts, inventory levels, and resource availability, ERP systems help manufacturers create optimal production schedules. This ensures that production runs smoothly, meets customer demand, and minimizes downtime.

Features of Manufacturing ERP

Setup:

- BOM Define

- Work center define

- Operation define

- Routings

- BOM Management

- Manufacturing Order

- Work Orders

Transactions:

- Production plan & control

- Gate inward

- Work Orders

- Batching

- Dispatch to Party

- Cost centers

- Quality Control

Reports:

- Production Expense Report

- Daily production Report

- Department Wise Production Report

- Waste report

- Quality Reports

- Each Dept Stock Level

- PPC status

- Separate P and Loss for Dept.

- Separate Balance sheet For Dept

Future Trends in ERP for Manufacturing

Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are transforming ERP systems, offering advanced analytics, predictive maintenance, and intelligent automation. These technologies enable manufacturers to make data-driven decisions, improve efficiency, and stay competitive.

Internet of Things (IoT) Integration

The integration of IoT with ERP systems provides real-time data from connected devices, improving visibility and control over manufacturing processes. IoT-enabled ERP systems can monitor equipment performance, track inventory, and optimize production in real time.

Cloud-based ERP Solutions

Cloud-based ERP solutions offer several advantages, including lower upfront costs, scalability, and remote access. Manufacturers can benefit from the flexibility and agility of cloud-based ERP, enabling them to respond quickly to changing market conditions and customer demands.

Book Your Free Demo

About Us

ERP software and systems are designed and implemented by Multi-Techno, a registered company. By combining data from financials, sales, CRM, inventories, and operations, businesses can increase productivity, make better decisions, and increase profitability with the aid of our ERP System, a single, integrated software platform.

Quick Links

Contact Us

Office # 100, 101 Second Floor Kohinoor 1, Faisalabad, Pakistan