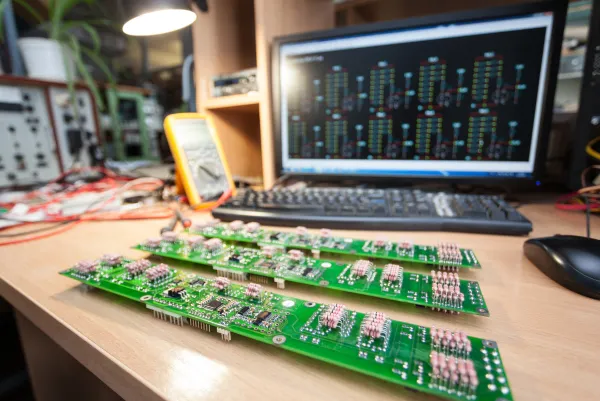

Multi-Techno Integrated Solution

Integrate your business with ERP

Multi-techno ERP Integrated Solutions enable smooth business operations. Boost productivity, simplify procedures, and improve the performance of your business.

Modules of ERP

Accounts and Finance System

Accounts Receivables

Accounts Payables

Inventory Management

Purchase Management

Sales Management

Production Management

HR and Payroll Module

General Ledger Module

Comprehensive Module Suite

User/Securities Management

Fixed Asset Module

Industries We Are Serving

These salient features highlight the ways in which Multi-techno ERP solutions may improve operational effectiveness, compliance, and overall business performance for a wide range of industries.

Optimize Growth with ERP:

- Easily transform your company’s operations with our affordable, cloud-based ERP software.

- Take advantage of unparalleled access to vital data, optimized procedures, and increased productivity.

- Adopt the Cloud Revolution for a productive and safe working environment.

Empower Your Team with ERP:

- Give your staff the freedom to concentrate on growth-promoting strategic activities.

- Safe, central data access is guaranteed by our cloud-based system, accessible from any location.

- Launching a new chapter in business brilliance.

Are you prepared to transform your company? Get in touch with us right now!

WHY CHOOSE Multi-techno

One Click Payroll

Analytical Dashboards

Customizable Reports

Automated Alerts & Notifications

Dynamic Workflow

Fast-Growing ERP Software

Geo Fencing

On-Cloud & On-premises

Employee Self Service

Premium Modules

Standerd Quality

Mobile Application

Our Satisfied Clients

Facts About Us

Dive into the essence of our success with ‘Facts About Us.’ Explore a rich tapestry of achievements, including 112+ happy clients and 100+ successfully completed projects, reflecting our commitment to excellence in the world of ERP solutions.

Registration With

Best cloud ERP software solution

About Us

ERP software and systems are designed and implemented by Multi-Techno, a registered company. By combining data from financials, sales, CRM, inventories, and operations, businesses can increase productivity, make better decisions, and increase profitability with the aid of our ERP System, a single, integrated software platform.

Quick Links

Contact Us

Office # 100, 101 Second Floor Kohinoor 1, Faisalabad, Pakistan